Our projects undergo detailed modelling and design processes, that strictly adhere to the standards of aluminum injection casting using CAD-3D technology.

Our projects undergo detailed modelling and design processes, that strictly adhere to the standards of aluminum injection casting using CAD-3D technology.

Mold Design

Mold Design

Our projects follow detailed modeling and design processes tailored to aluminum injection casting standards using CAD-3D technology. By using SIEMENS UNIGRAPHICS, SOLIDWORKS, and MAGMA Soft simulation, we optimize our mold design and ensure precise and cost-effective results. Advanced alloys and modern coating techniques reduce time and costs. We partner with accredited test labs and our trusted supplier network, operating 25 machines from 160T to 1,100T clamping force, to uphold top-quality aluminum injection casting standards.

Our projects follow detailed modeling and design processes tailored to aluminum injection casting standards using CAD-3D technology. By using SIEMENS UNIGRAPHICS, SOLIDWORKS, and MAGMA Soft simulation, we optimize our mold design and ensure precise and cost-effective results. Advanced alloys and modern coating techniques reduce time and costs. We partner with accredited test labs and our trusted supplier network, operating 25 machines from 160T to 1,100T clamping force, to uphold top-quality aluminum injection casting standards.

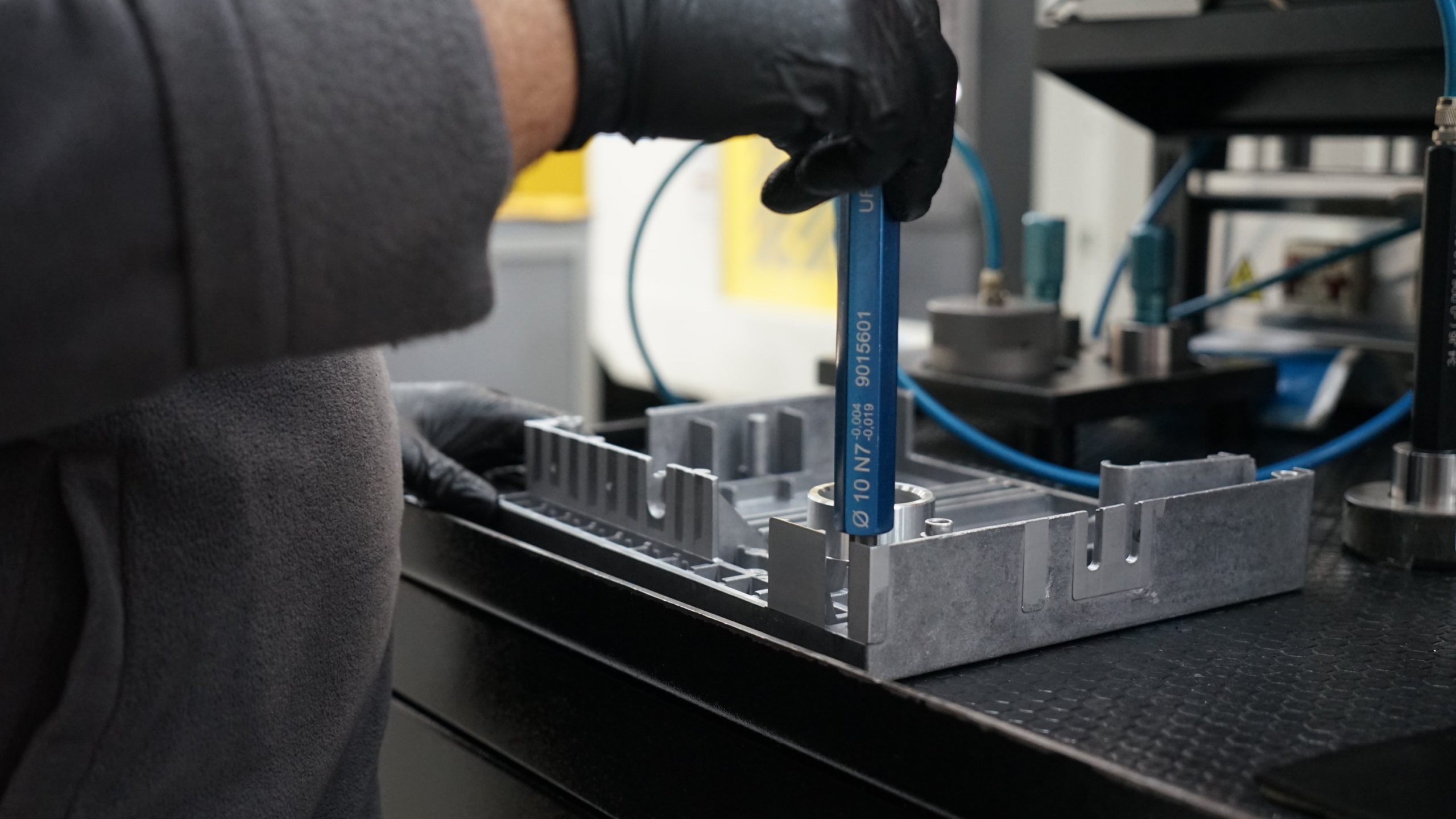

Machining

Machining

Projects requiring precise form and position tolerances demand careful planning. We invest time and manpower in the design and production planning of molds, machining fixtures and cutting tools. Our quality is achieved through collaborations with renowned partners like NIKKEN, MAKINO, BROTHER, FANUC, TAKISAWA, CERATISIT and ROEMHELD. With our machinery and esteemed local business partners, each distinguished in machining, we collectively operate a robust capacity of 15 CNC machines including automatic loading.

Projects requiring precise form and position tolerances demand careful planning. We invest time and manpower in the design and production planning of molds, machining fixtures and cutting tools. Our quality is achieved through collaborations with renowned partners like NIKKEN, MAKINO, BROTHER, FANUC, TAKISAWA, CERATISIT and ROEMHELD. With our machinery and esteemed local business partners, each distinguished in machining, we collectively operate a robust capacity of 15 CNC machines including automatic loading.

Surface Treatment

Surface Treatment

In industrial applications, the visual compound of parts is increasingly crucial, making surface quality a critical consideration. In order to achieve the appearance our customers expect to see, we use a combination of surface treatments. Our offers include hanging & drum-type shot blasting, vibration processes, various surface treatment techniques through our suppliers, such as electrostatic powder paint, wet paint, and anodizing. Our goal is to deliver comprehensive solutions that make our parts not only functional but also beautiful.

In industrial applications, the visual compound of parts is increasingly crucial, making surface quality a critical consideration. In order to achieve the appearance our customers expect to see, we use a combination of surface treatments. Our offers include hanging & drum-type shot blasting, vibration processes, various surface treatment techniques through our suppliers, such as electrostatic powder paint, wet paint, and anodizing. Our goal is to deliver comprehensive solutions that make our parts not only functional but also beautiful.

Tool Management

Tool Management

Tool Management is the cornerstone of our company. Our Smart Tool Storage System equipped with our customized software, tracks each tool’s lifetime using QR Codes, allowing us to swich tools before they wear out. This ensures consistent quality and reduces setup times from hours to minutes. In recent years, we’ve made strategic investments in Presetters, Tool Holding Systems, and Fine Balancing Machines.

Presetter:

Nikken Elbo Controlli allows us to fine-tune tools before production, conserving machining capacities and ensuring efficient utilization.

Tool Holding Systems:

We have expanded our tool holding systems from hydraulic clamping to ball holder collet systems, and further to shrink systems. Our Bilz Shrink unit reaches even the most narrow areas in machining with minimal runout.

Fine Balancing:

When high spindle speed and narrow tolerances come together, meeting specifications becomes challenging. In our Tooling Department, tools are finely balanced to ensure accurate machining and protection of spindles over time.

Tool Management is the cornerstone of our company. Our Smart Tool Storage System equipped with our customized software, tracks each tool’s lifetime using QR Codes, allowing us to swich tools before they wear out. This ensures consistent quality and reduces setup times from hours to minutes. In recent years, we’ve made strategic investments in Presetters, Tool Holding Systems, and Fine Balancing Machines.

Presetter:

Nikken Elbo Controlli allows us to fine-tune tools before production, conserving machining capacities and ensuring efficient utilization.

Tool Holding Systems:

We have expanded our tool holding systems from hydraulic clamping to ball holder collet systems, and further to shrink systems. Our Bilz Shrink unit reaches even the most narrow areas in machining with minimal runout.

Fine Balancing:

When high spindle speed and narrow tolerances come together, meeting specifications becomes challenging. In our Tooling Department, tools are finely balanced to ensure accurate machining and protection of spindles over time.

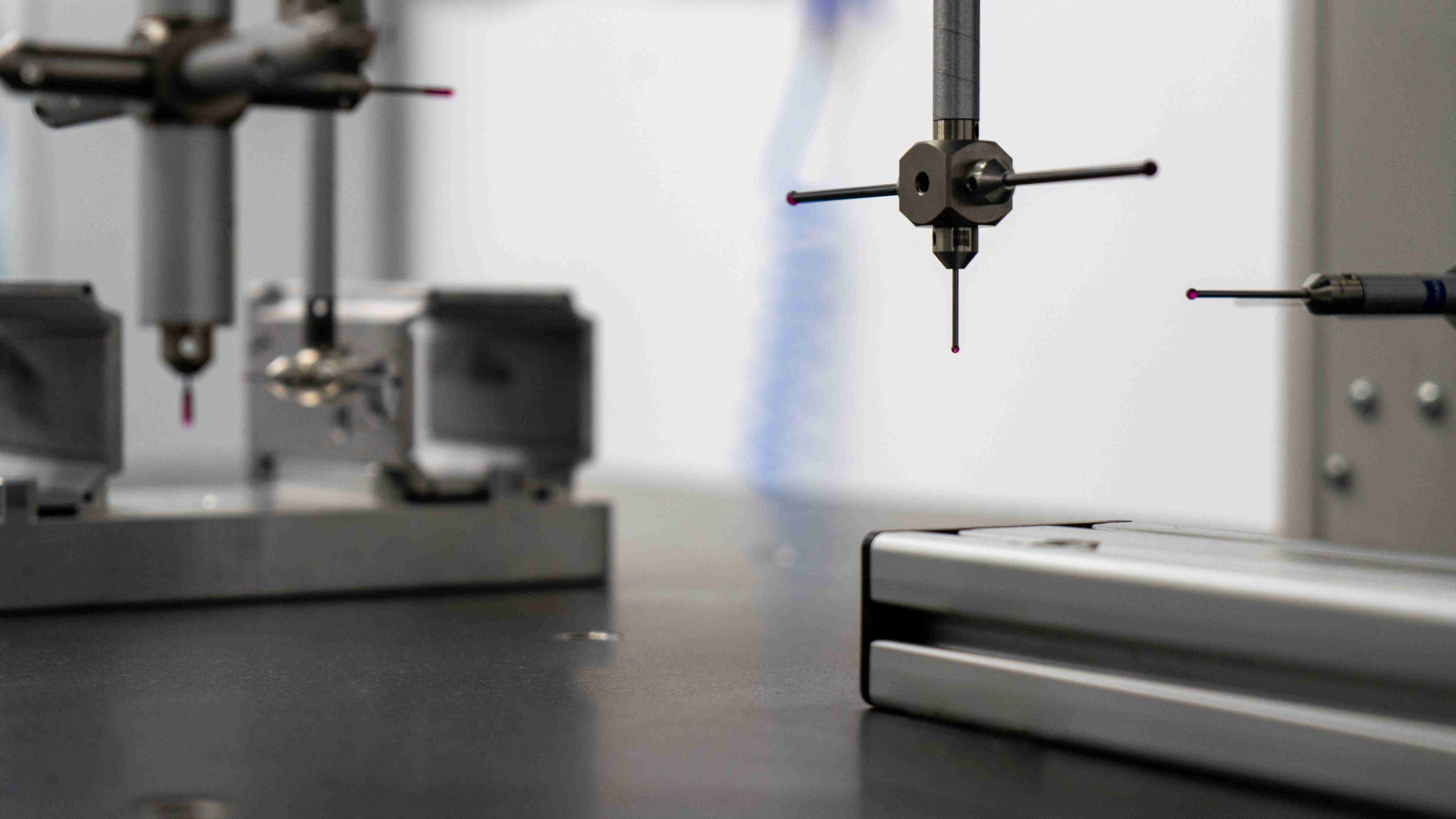

Q-LAB

Q-LAB

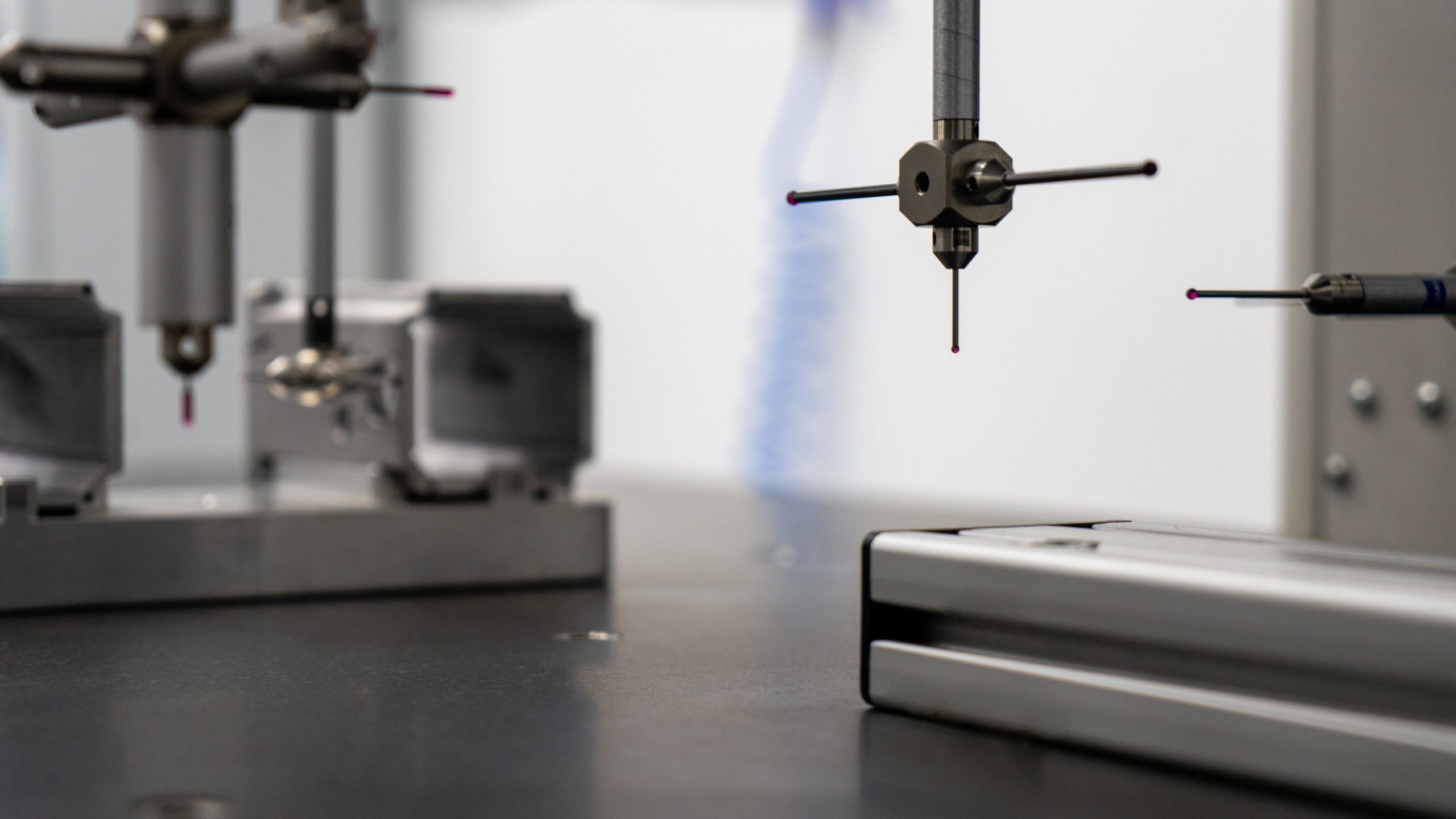

Our parts undergo 3D measurements with our state-of-the-art ZEISS measuring device featuring a 1.7 µm precision active head. Measurement technicians use technical drawings and customer specifications as their criteria to ensure accuracy. Parts are stored in a controlled air-conditioned environment before measurement to maintain precision for narrow tolerances.

Efficiency is Key.

We stay efficient with a special air gauge measurement system within the production area for real-time recording and evaluation. For contour measurements, we use the MahrSurf CD140 Contourgraph for accurate assessments and for dimensional accuracy, we make use of the 3D Laser Scanner Creaform with Polyworks Software.

Our parts undergo 3D measurements with our state-of-the-art ZEISS measuring device featuring a 1.7 µm precision active head. Measurement technicians use technical drawings and customer specifications as their criteria to ensure accuracy. Parts are stored in a controlled air-conditioned environment before measurement to maintain precision for narrow tolerances.

Efficiency is Key.

We stay efficient with a special air gauge measurement system within the production area for real-time recording and evaluation. For contour measurements, we use the MahrSurf CD140 Contourgraph for accurate assessments and for dimensional accuracy, we make use of the 3D Laser Scanner Creaform with Polyworks Software.

Consultancy

Consultancy

Using our expertise in core production technologies like mold design, injection molding, CNC machining and surface processing, we have become trusted consultants in our industry. Our services meet high demand and help us improve processes and reduce costs. We focus on high precision and critical product machining, offering services, such as mold and machining fixture design using Siemens Unigraphics, casting process optimization with Magma Soft, streamlining production chain processes, and enhancing quality management systems for our suppliers. Consultancy is esential in shaping and expanding our supplier network.

Using our expertise in core production technologies like mold design, injection molding, CNC machining and surface processing, we have become trusted consultants in our industry. Our services meet high demand and help us improve processes and reduce costs. We focus on high precision and critical product machining, offering services, such as mold and machining fixture design using Siemens Unigraphics, casting process optimization with Magma Soft, streamlining production chain processes, and enhancing quality management systems for our suppliers. Consultancy is esential in shaping and expanding our supplier network.