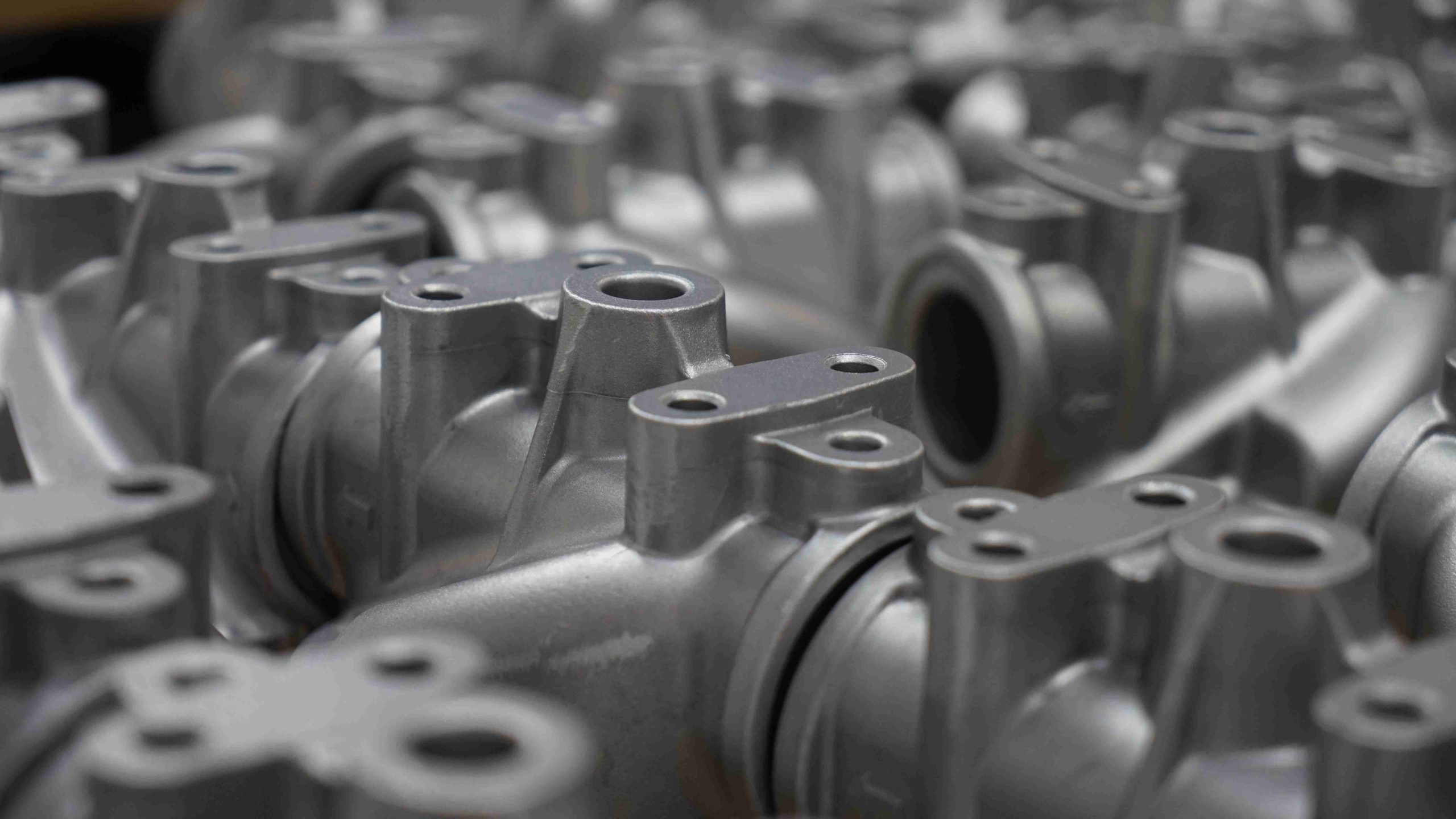

We set new standards for customized aluminum die casting and machining, driven by passion for excellence.

We set new standards for customized aluminum die casting and machining, driven by passion for excellence.

About Us

About Us

Having grown up in Germany, Osman Kalankan, brings over 35 years of experience and technological Know How in tool design and machining to the table. 2014 he founds KALANKAN Ltd. in a small office with a team of two, focusing on customized aluminum die casting and machining projects with tricky engineering.

Today we are based in Kocaeli, a logistic hub close to Istanbul, where we generate a turnover of 5,8 million euros in 2022, operating on 3500 square meters with our dedicated and highly motivated team of 42 members. Their hard work, combined with our robust supplier network, enables us to export 100% of our products globally, primarily targeting Central Europe, where we have established a strong reputation for quality and customer centered approach.

We are nothing without our Team

We are nothing without our Team

Our determined and highly motivated team is the core of our success. In our workspace, experience meets fresh, young, and dynamic spirit. Each and every single team member is dedicated to achieving excellence and pushing their own limits.

We prioritize identifying and cultivating the unique strengths and individual needs of everybody here by nurturing an environment of equality and trust.

Our working culture is framed by a supportive leadership that results in high performance, motivation, and loyalty, creating deep connections and strong relationships that go beyond the workplace.

Everyone at KALANKAN has the right of feeling respected and valued at work. With this in mind, we have created a working atmosphere all of our team members look forward to experience every day.

Vision

Our Vision is to create relationships built on trust.

Committed to innovation and excellence, we aim to grow continuously, while consistently surpassing our own achievements. By prioritizing customer satisfaction we strive to set new standards in our industry. Our dedication to learning and evolving ensures we remain leaders in our field, establishing ourselves as an employer and partner of choice in the market.

Mission

Creating efficient manufacturing processes requires continuous improvement.

To achieve our goal of excellence and customer satisfaction, we evaluate and reconsider our operations constantly which contributes our customers demand of high quality aluminum die casting machining parts. Our team members are our greatest asset. To create a work environment our team members enjoy to be a part of, we offer flat hierarchies, opportunities to grow, and trainings as well as coachings and transformational leadership. We prioritize the ongoing training and education of our team and suppliers, recognizing that their development is crucial to our collective success. As an employer, we aim to build an environment that attracts top talents, offering continuous learning opportunities for professional development and career fulfilment.

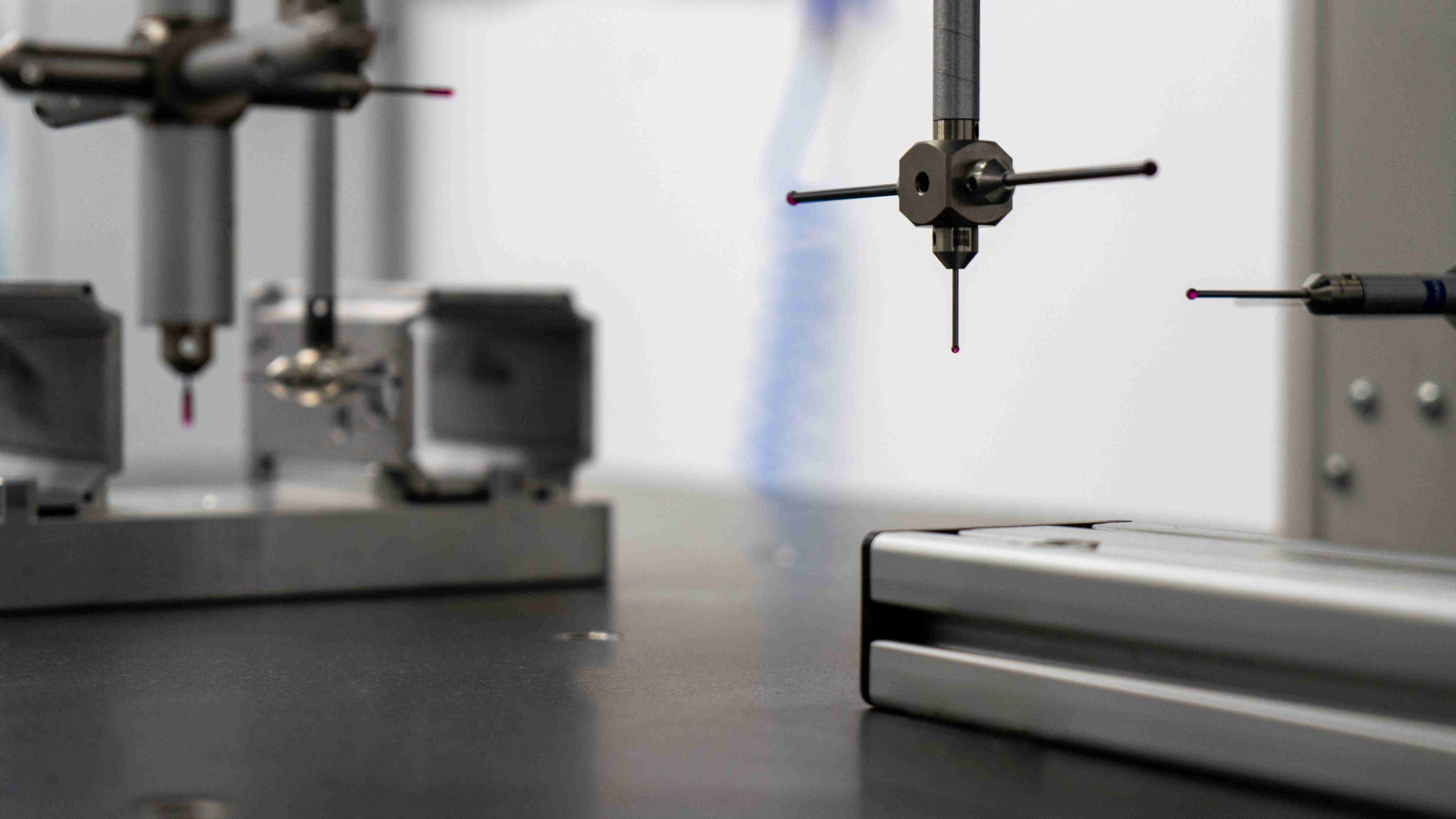

Quality Management

Quality Management

Our Quality Management system is designed to target 100% customer satisfaction.

With both our internal and external processes ensuring strict compliance with technical specifications and our customers individual needs. To create and maintain quality, we do a full PPAP at the beginning of each project, including PFMEAs to minimize risks right at the beginning and finish by analyzing and solving every quality issue with the 8D or A3 method.

These principles are known, understood, and applied in every part of our organization and supplier network.

We operate according to the ISO 9001:2015 standard and plan to integrate ISO 14001, ISO 27001, and ISO 45001 into our Quality Management System.

To ensure top-notch quality across all aspects of our production, we handle the management of outsourced processes and maintain a close relationship with our suppliers, which includes handling of Failure Analyses and Problem-Solving actions.

To ensure top-notch quality across all aspects of our production, we handle the management of outsourced processes and maintain a close relationship with our suppliers, which includes handling of Failure Analyses and Problem-Solving actions.

Supply Chain Management

Supply Chain Management

01

01

We are directly involved in the management of our outsourced processes in the project phase and further on provide daily support when going into serial production, helping our suppliers to evolve and improve their quality management system and internal processes.

We are directly involved in the management of our outsourced processes in the project phase and further on provide daily support when going into serial production, helping our suppliers to evolve and improve their quality management system and internal processes.

02

02

For seamless document exchange with our customers covering quotations, orders, annual demand planning and supplier evaluations we rely on SupplyOn.

For seamless document exchange with our customers covering quotations, orders, annual demand planning and supplier evaluations we rely on SupplyOn.

03

03

To manage our processes, ensure just-in-time production, and maintain internal transparency, we make use of SAP Business One. Our warehouse operates on a FIFO basis, not only for traceability but also to guarantee that our customers receive the up-to-date, confirmed versions of their products.

To manage our processes, ensure just-in-time production, and maintain internal transparency, we make use of SAP Business One. Our warehouse operates on a FIFO basis, not only for traceability but also to guarantee that our customers receive the up-to-date, confirmed versions of their products.

Life-Long Learning

Life-Long Learning